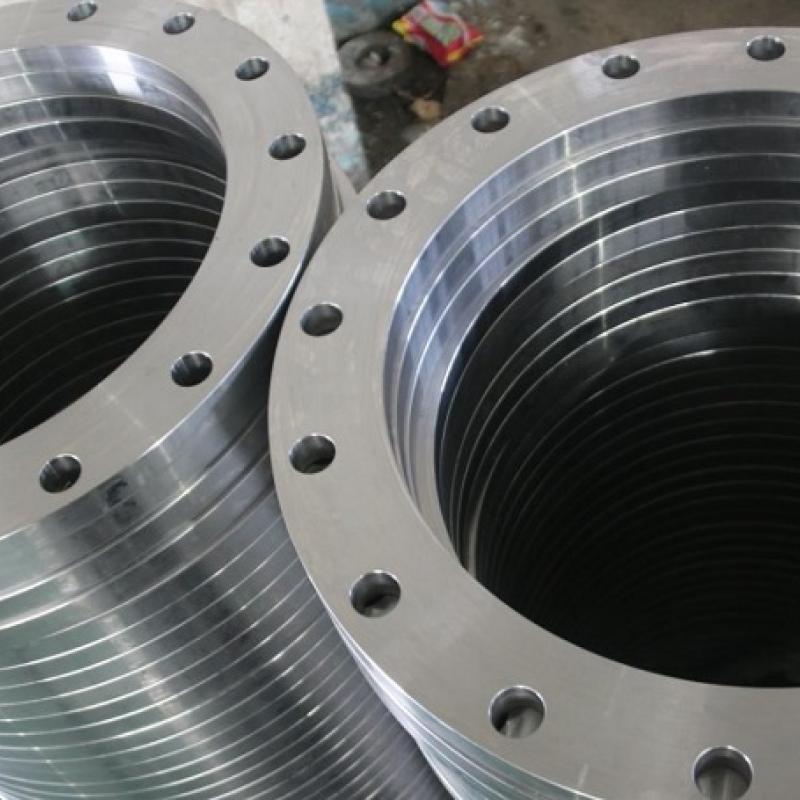

The main use of flange is to connect pumps, pipes, valves, and other equipment to make a pipework system. Usually, flanges are threaded or welded, and you can connect two flanges by bolting them with gaskets and providing a seal that gives easy access to the piping system.1. Standard:JIS B2220 2. Type:SOP3. Pressure Class:1k;5k;10k;16k;30K:40K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS4007. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9. Delivery time:30 ~60 days after confirm the order1.

Contact Now

In the flange, FF represents a flat sealing surface, whilst in the Japanese standard, SOP is a plate kind flat welding flange, SOH is a neck flat welding flange, and BL is a flange cowlSocket welding flange (SW)Socket welding flangeSocket Welding FlangeSealing floor form: protruding floor (RF), concave and convex floor (MFM), tongue and groove floor (TG), ring connection floor (RJ)Materials: Carbon Steel: ASTM A105, 20#, Q235, 16Mn, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70;Alloy steel: ASTM

Contact Now

Flanges normally need to be produced in accordance with standards, and more often in accordance with national standards to produce flanges, that is: according to the size and tolerance range required by national standards to produce flanges, such standard flanges In use, although they can also be used, but more often, the requirements of industrial production for flanges are different, so the specifications of flanges will also change, for example, industrial production can not use standard flanges, only large flanges; Some industrial productions can only use smaller flanges, therefore, faced

Contact Now

We have reliable manufacturers to purchase directly, support customization, have good quality, have real materials, and are durable.Flange, additionally recognized as flange disc or flange. Flanges are components that are interconnected between shafts and shafts for connections between pipe ends; There are additionally flanges used on the inlet and outlet of tools for the connection between two devices, such as reducer flanges.

Contact Now

Flat welded flanges are appropriate for pipeline structures with pretty low strain degrees and minimal stress fluctuations, vibrations, and vibrations.

Contact Now

Japanese Industrial Standards (JIS) is the most important and authoritative national standard in Japan. Developed by the Japan Industrial Standards Survey (JISC).1. Standard:JIS B2220 2. Type:SOP SOH3. Pressure Class:20K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9. Delivery time:30 ~60 days after confirm the order1. Standard:JIS B2220 2. Type:SOP SOH3. Pressure Class:20K4. Dimension:10A-1200A5.

Contact Now

American standard flange is a component that connects pipes to each other and is connected to the pipe end. The American standard flange has eyelets and bolts to tightly connect the two flanges. The flanges are sealed with gaskets. American standard flanges can be cast or threaded or welded.In industrial pipelines, American standard flange connections are widely used. In the home, the diameter of the pipeline is small and it is low pressure, so flange connections cannot be seen. If in a boiler room or production site, flange connected pipes and equipment can be seen everywhere1.

Contact Now

Flange, moreover acknowledged as flange flange or flange. the flange is the connecting thing amongst the shaft and the shaft, it is used for the relationship amongst the pipe ends; the flange on the device inlet and outlet is additionally used for the relationship amongst gadget, inclusive of the reducer flange. flange connection or flange joint refers to the detachable connection of flange, gasket and bolt as a set of combined sealing shape.

Contact Now

Shandong Shengli Forging Co.ltd. was once headquartered in 2008, now there are eighty workers, worldwide income personnel 5 , pleasant inspection personnel 6. Monthly output can attain 600 tons. Production, packaging, laboratory trying out gear available. We specialize in producing carbon metal flanges.The application fields of ring forgings are:Diesel engine ring forging: a kind of diesel engine forging, diesel engine diesel engine diesel engine is a kind of power machinery, it is commonly used as an engine.

Contact Now

The flat flange has sufficient strength and must not deform during the tightening process. The sealing surface of the flange should be smooth and clean. When installing stainless steel flanges, oil stains and rust spots should be carefully cleaned. Gaskets shall have good oil resistance and aging resistance, as well as relatively good elasticity and mechanical strength.

Contact Now

Our business enterprise can produce a number of specifications of stainless steel, alloy steel, and carbon metal flange merchandise in accordance to standards; The product has passed through strict first-class inspection, continuously striving for excellence in dimension and quality, and is broadly bought each domestically and internationally, receiving unanimous reward from clients each domestically and internationally.Flange, moreover considered as flange disc or flange.

Contact Now

The ANSI Class rating of a flange is defined as the maximum amount of pressure that the flange can withstand at increasing temperatures. There are seven primary pressure classes for flanges. They are 150,300,400,600,900,1500,and2500.American standard flange connection is a detachable connection. It is the process of fixing two pipes, fittings, or equipment onto a flange, with flange gaskets added between the two flanges and bolts fastened together to complete the connection. American standard flange connection is an important connection method for pipeline construction.

Contact Now

Flange connection is a removable joint that first fixes two pipes, fittings, or tools to a flange, then provides a flange gasket between the two flanges, and sooner or later makes use of bolts to tighten the two flanges to tightly join them. The connection between stationary pipelines and rotating or reciprocating gear can be achieved.1. Sliding line blanking:Cut the ingots to a reasonable size and weight according to product requirements;2.

Contact Now

1. Standard:JIS B2220 2. Type:F-TYPE S/40 S/803. Pressure Class:5K 10K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9. Delivery time:30 ~60 days after confirm the order1. Standard:JIS B2220 2. Type:F-TYPE S/40 S/803. Pressure Class:5K 10K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9.

Contact Now

According to the standard specifications of the GOST12820 and GosT12821 series, the thickness, aperture, thread, and other standards related to flange size are usually strict. These regulations can ensure that the size, quality, and performance of the flange meet the standards, ensuring the safe operation of the pipeline1. Standard:GOST 12820- 80 GOST 12821- 80 2. Type:Plate flange,Blind,Lap Joint flange3. Pressure Class:PN10 PN16 PN25 PN40 PN634. Dimension:DN10-DN12005. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6.

Contact Now

European standard EN 1092-1 – concerning flanges for pipes – establishes the requirements for steel flanges based on their nominal pressure (PN) and dimension (DN). Moreover, it defines the different kinds of flanges and their sealing surfaces, tolerances, threading and labelling1. Standard:EN1092-12. Type:Type 01 ;Type 05;3. Pressure Class:PN6;PN10; PN16; PN25; PN404. Dimension:DN10-DN20005. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:RST 37.2; P245GH ; S235JR7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9.

Contact Now

The name "flat welding" in the name of flat welding flange represents the welding form of the flange, which is different from butt welding flange because the shape and size of the flange are different due to different welding forms, and the usage and pressure resistance are also different.The sealing surface form of plate type flat welded steel pipe flange PL is divided into two types: raised face (RF) and full face (FF).The sealing surface forms of SO with neck flat welded steel pipe flanges are divided into raised face (RF), raised and raised face (FM, M), tenon and groove face (T,

Contact Now

Shandong Shengli Forging Co., Ltd. specializes in producing various types of flanges, gear rings, and forgings. We welcome customers to visit and inspect1. According to the chemical industry (HG) industry standard: integral flange (IF), threaded flange (Th), plate flat welding flange (PL), neck butt welding flange (WN), neck flat welding flange (SO), socket welding flange (SW), butt welding ring loose flange (PJ/SE), flat welding ring loose flange (PJ/RJ), lining flange cover (BL (S)), flange cover (BL) [2].2.

Contact Now

SABS 1123 Flanges are forged, threaded, screwed or plate flanges as manufactured. These additionally vary in the face kind of the flange such as the flat face, raised face and the ring kind joint. There are one-of-a-kind practical kinds in the SANS 1123 Flanges such as socket weld ring flange, threaded ring flange, blind flange, weld neck flange, slip on flange, lap joint flange and so on. The dimensions of the flanges differ in accordance to the ASME B16.5 standard.

Contact Now

Ring forgings are a product in the forging enterprise and a kind of forging. It is a round object made of steel billets (excluding plates) that are subjected to exterior pressure and molded thru plastic deformation to obtain excellent compressive force. This pressure is commonly completed via the use of a hammer or pressure. The forging manner builds extraordinary particle buildings and improves the bodily houses of the metal.

Contact Now

Ring forgings are a product in the forging enterprise and a kind of forging. It is a round object made of metallic billets (excluding plates) that are subjected to exterior pressure and molded via plastic deformation to reap splendid compressive force. This pressure is normally completed thru the use of a hammer or pressure. The forging procedure builds outstanding particle constructions and improves the bodily homes of the metal.

Contact Now

Couplings are a forged steel fitting used to connect two lengths of pipe, and Half-coupling is screwed onto the pipe, while the other end is made to be tightly inserted, or welded, onto the other end to pipe or vessel.

Contact Now

(1) Large weight range. Forgings can vary from a few grams to heaps of tons.(2) Higher satisfactory than castings. The mechanical homes of forgings are higher than these of castings, and they can face up to massive affect forces and different heavy loads. Therefore, forgings are used for all essential and burdened parts.For excessive carbide steel, forgings have higher high-quality than rolled products. For example, high-speed metal rolled (or forged) substances can solely meet the usage necessities after change and forging.

Contact Now