Our company can produce various specifications of stainless steel, alloy steel, carbon steel flange series products according to standards; The products have undergone strict quality inspection, constantly improving in size and quality, and are widely sold at home and abroad, obtaining consistent praise from customers at home and abroad.As an iron plate welding flange, many clients have questions about whether or not the great of the iron plate welding flange is higher than that of the solid welding flange.

Contact Now

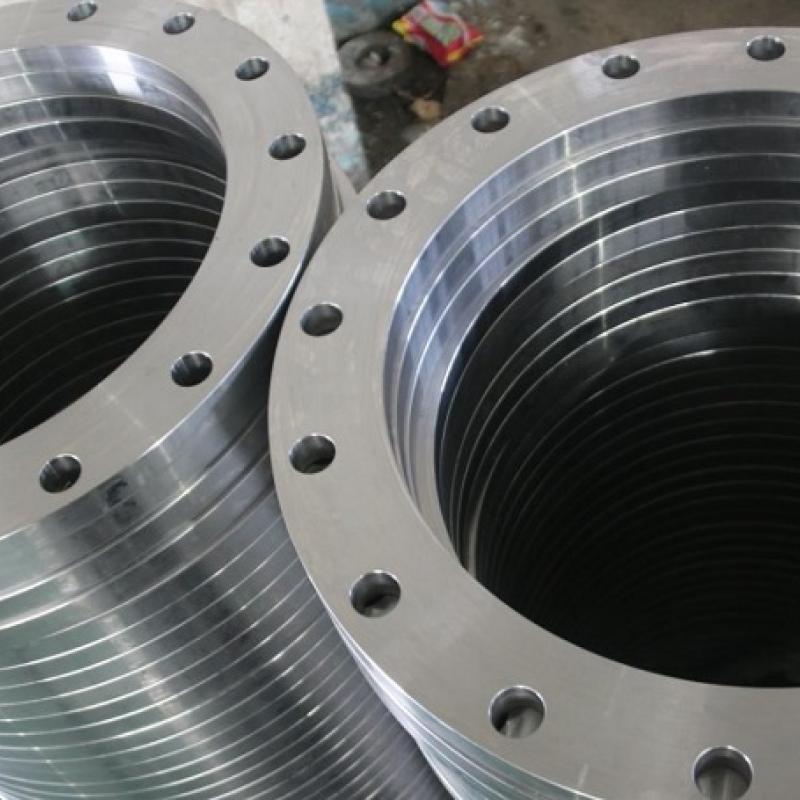

1. Standard:JIS B22202. Type:SOP SOH3. Pressure Class:5K 10K 16K 20K 30K 40K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9. Delivery time:30 ~60 days after confirm the order1. Standard:JIS B22202. Type:SOP SOH3. Pressure Class:5K 10K 16K 20K 30K 40K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9.

Contact Now

Pipe flanges: (JIS B2201, JIS B2220, etc.) are self-contained and do not belong to either "American style flanges" or "European style flanges"Nominal diameter: (DN10~DN1000) mmNominal pressure levels: 2K, 5K, 10K, 16K, 20K, 30K, 40K, 63K, a total of 8 levelsFlange sealing surface: 5 types: smooth surface, large convex surface, small convex surface, concave convex surface, and tenon groove surfaceFlange types: 6 types: flat welding, socket welding, butt welding, threaded connection, loose sleeve, and blind flange1. Standard:JIS B22202. Type:SOP SOH3.

Contact Now

Blind flange, additionally recognised as blind flange, is formally referred to as flange cover. It is a flange barring a gap in the middle, used to seal pipeline plugs. There are many sorts of sealing surfaces, which include flat, convex, concave convex, tenon groove, and ring connection surfaces.1. Standard:JIS B2220 2. Type:BLIND3. Pressure Class:5k;10k;16k;30K:40K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS4007. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9.

Contact Now

Flat welded flanges are suitable for pipeline systems with relatively low pressure levels and minimal pressure fluctuations, vibrations, and vibrations. The advantage of flat welding flanges is that they are easier to align during welding and assembly, and their price is relatively cheap, making them widely used.1. Standard:JIS B22202. Type:SOP SOH3. Pressure Class:5K 10K 16K 20K 30K 40K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9.

Contact Now

The name "flat welding" in the name of flat welding flange represents the welding form of the flange, which is different from butt welding flange because the shape and size of the flange are different due to different welding forms, and the usage and pressure resistance are also different.The sealing surface form of plate type flat welded steel pipe flange PL is divided into two types: raised face (RF) and full face (FF).The sealing surface forms of SO with neck flat welded steel pipe flanges are divided into raised face (RF), raised and raised face (FM, M), tenon and groove face (T,

Contact Now

Our company has various types of forging equipment such as presses and air hammers, which can produce various types of flanges and forgings. We also have various CNC processing equipment and a complete inspection system. We welcome customers to purchase.(1) Casting flange and forged flangeThe cast flange, blank shape and size is accurate, the processing volume is small, the cost is low, but there are casting defects (pores. Crack.

Contact Now

Flange connection is a removable joint that first fixes two pipes, fittings, or tools to a flange, then provides a flange gasket between the two flanges, and sooner or later makes use of bolts to tighten the two flanges to tightly join them. The connection between stationary pipelines and rotating or reciprocating gear can be achieved.1. Sliding line blanking:Cut the ingots to a reasonable size and weight according to product requirements;2.

Contact Now

1. Standard:JIS B22202. Type:SOP SOH3. Pressure Class:5K 10K 16K 20K 30K 40K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9. Delivery time:30 ~60 days after confirm the order1. Standard:JIS B22202. Type:SOP SOH3. Pressure Class:5K 10K 16K 20K 30K 40K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9.

Contact Now

1. Standard:JIS B2220 2. Type:F-TYPE S/40 S/803. Pressure Class:5K 10K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9. Delivery time:30 ~60 days after confirm the order1. Standard:JIS B2220 2. Type:F-TYPE S/40 S/803. Pressure Class:5K 10K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9.

Contact Now

As for iron plate welding flanges, many customers are questioning whether the quality of iron plate welding flanges is better than forged welding flanges. In fact, the quality of iron plate welding flanges is the same as that of forged welding flanges. However, where is the material of iron plate welding flanges that cannot be guaranteed? This means that the material of iron plate welding flanges is the least guaranteed, because in general, the density of iron plate welding flanges is not an issue.

Contact Now

1. Standard:JIS B2220 2. Type:BLIND3. Pressure Class:5k;10k;16k;30K:40K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS4007. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9. Delivery time:30 ~60 days after confirm the order1. Standard:JIS B2220 2. Type:BLIND3. Pressure Class:5k;10k;16k;30K:40K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS4007. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9.

Contact Now

1. Standard:JIS B2220 2. Type:F-TYPE S/40 S/803. Pressure Class:5K 10K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9. Delivery time:30 ~60 days after confirm the order1. Standard:JIS B2220 2. Type:F-TYPE S/40 S/803. Pressure Class:5K 10K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9.

Contact Now

Flat welded flanges are appropriate for pipeline structures with pretty low strain degrees and minimal stress fluctuations, vibrations, and vibrations.

Contact Now

A flange is a method of connecting pipes, valves, pumps and other equipment to form a piping system. It also provides easy access for cleaning, inspection or modification. Flanges are usually welded or screwed. Flanged joints are made by bolting together two flanges with a gasket between them to provide a seal.1. Standard:JIS B2220 2. Type:SOP SOH3. Pressure Class:5k;10k;16k;30K:40K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9.

Contact Now

1. Standard:JIS B2220 2. Type:SOP SOH3. Pressure Class:5K 10K 16K 20K 30K 40K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9. Delivery time:30 ~60 days after confirm the order1. Standard:JIS B2220 2. Type:SOP SOH3. Pressure Class:5K 10K 16K 20K 30K 40K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9.

Contact Now

Japanese Industrial Standards (JIS) is the most important and authoritative national standard in Japan. Developed by the Japan Industrial Standards Survey (JISC).1. Standard:JIS B2220 2. Type:SOP SOH3. Pressure Class:20K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9. Delivery time:30 ~60 days after confirm the order1. Standard:JIS B2220 2. Type:SOP SOH3. Pressure Class:20K4. Dimension:10A-1200A5.

Contact Now

The forging technique usually consists of the following processes: deciding on amazing metal billets for cutting, heating, forming, and cooling after forging. The forging method techniques consist of free forging, die forging, and membrane forging. During production, special forging strategies are chosen based totally on the dimension of forging exceptional and the range of manufacturing batches.1. Standard:JIS B2220 2. Type:BLFF3. Pressure Class:5k;10k;16k;30K:40K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6.

Contact Now

The foremost use of flange is to join pumps, pipes, valves, and different gear to make a pipework system. Usually, flanges are threaded or welded, and you can join two flanges by means of bolting them with gaskets and offering a seal that offers convenient get admission to to the piping machine1. Standard:JIS B22202. Type:SOP SOH3. Pressure Class:5K 10K 16K 20K 30K 40K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9.

Contact Now

One of its functions is to seal the end of the pipeline, and the other is to facilitate the removal of debris in the pipeline during maintenance. In terms of sealing effect, it has the same effect as the head and pipe cap. However, the head cannot be disassembled, and the flange blind plate is fixed with bolts, making it easy to disassemble. The blind flange materials include carbon steel, alloy steel, stainless steel, plastic, and so on1. Standard:JIS B22202. Type:SOP SOH3. Pressure Class:5K 10K 16K 20K 30K 40K4. Dimension:10A-1200A5.

Contact Now

1. Standard:JIS B22202. Type:SOP SOH3. Pressure Class:5K 10K 16K 20K 30K 40K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9. Delivery time:30 ~60 days after confirm the order1. Standard:JIS B22202. Type:SOP SOH3. Pressure Class:5K 10K 16K 20K 30K 40K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8. Payment:L/C, T/T9.

Contact Now

Flat welded flanges are appropriate for pipeline structures with particularly low stress degrees and minimal stress fluctuations, vibrations, and vibrations. The benefit of flat welding flanges is that they are less difficult to align at some stage in welding and assembly, and their charge is tremendously cheap, making them extensively used.1. Standard:JIS B22202. Type:SOP SOH3. Pressure Class:5K 10K 16K 20K 30K 40K4. Dimension:10A-1200A5. Surface Treament:Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc.6. Raw Material:SS400/SF440A7. Packing:Wooden Case, Pallet.8.

Contact Now

Flange blind (blind flange), also known as blind flange, real name is blind. It is a form of connection of flanges. In fact, it is a flange without a hole in the middle.One of its functions is to block the end of the pipeline, and the other is to easily remove debris in the pipeline during maintenance. In terms of plugging effect, it has the same effect as the head and cap. But the head is not disassembled, and the flange blind is bolted and easy to disassemble.

Contact Now

Advantages of high neck flanges The high neck flange, due to its overall shape and high neck height, greatly improves the stiffness and load-bearing capacity of the flange. Suitable for assembly lines and automated production, the production efficiency of component assembly and welding processes has been greatly improved. The insertion form of relatively flat flange and steel pipe reduces the consumption of welding materials, greatly reduces the welding workload and Labor burden, reduces the welding stress, and the structure is not easy to deform.

Contact Now