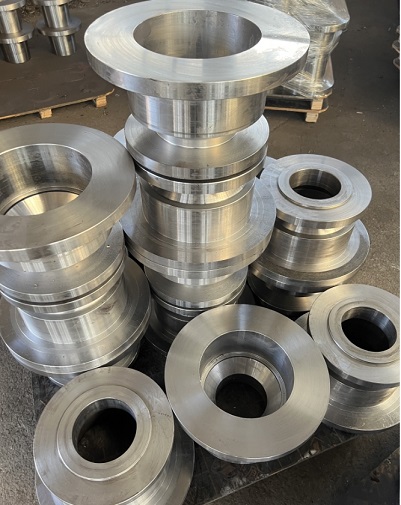

Machinery Parts

1. Improve the internal structure and mechanical properties of forgings. After forging processing, the microstructure and properties of the forging blank are improved and improved. Forging processing can eliminate defects such as pores, shrinkage cavities, and dendrites inside the metal ingot. Due to the plastic deformation and recrystallization of the metal, coarse grains can be refined to obtain a dense metallic structure, thereby improving the mechanical properties of the forging. When designing parts, selecting the correct direction of force and fiber structure can improve the impact resistance of the parts.

2. The utilization rate of materials is high. Metal plastic forming mainly relies on the rearrangement of the relative positions of the metal structure, without the need to cut off the metal.

3. High productivity. Forging processing is generally carried out using a press and a forging hammer for forming processing.

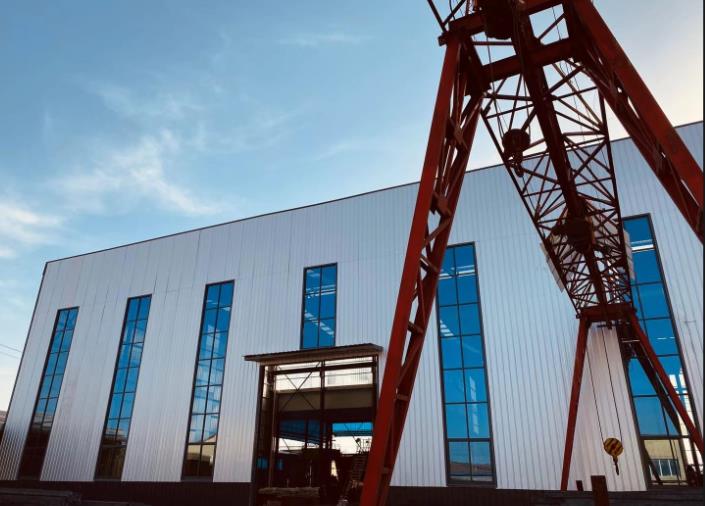

4. The accuracy of blanks or forgings is relatively high. Shanxi Yongxinsheng Forging applies advanced technology and equipment, which can achieve less or no cutting processing.

5. The metal materials used for forging should have good plasticity, so that under external forces, plastic deformation can occur without rupture. Among commonly used metal materials, cast iron is a brittle material with poor plasticity and cannot be used for forging. Copper, aluminum, and their alloys in steel and non-ferrous metals can be processed under pressure in either the cold or hot state.

6. Not suitable for forming forgings with complex shapes. Forging processing is formed in a solid state, and compared to casting, the flow of metal is limited, and generally requires measures such as heating to achieve it. It is difficult to manufacture parts or blanks with complex shapes, especially those with complex internal cavities.