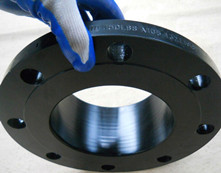

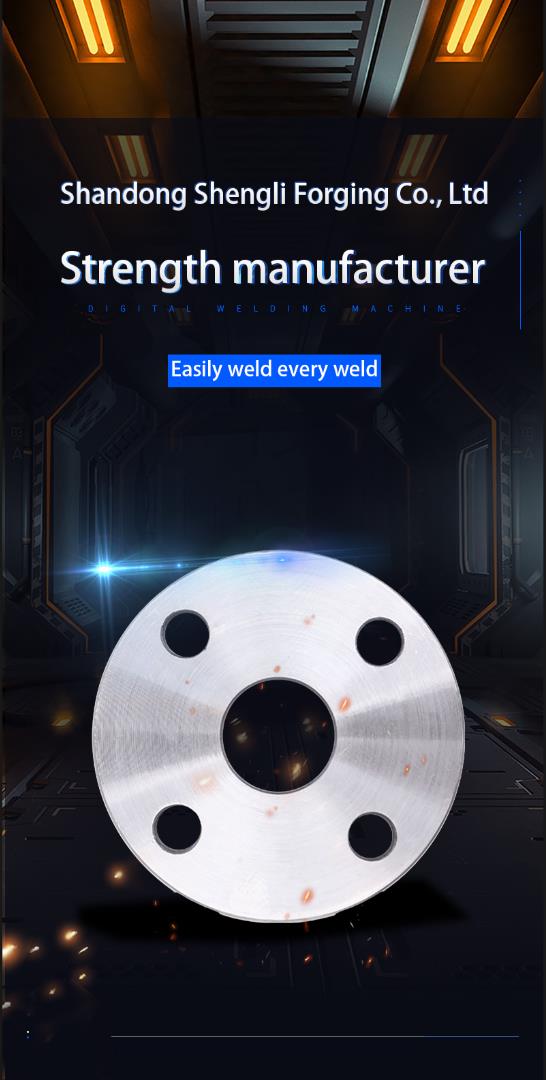

ANSI B16.5 Flange Black Paint

During installation, it is necessary to pay attention to factors such as the position, direction, and tightening force of the flange to ensure tight connection and avoid safety accidents caused by loose connections.

Flange connection is to fix two pipes, pipe fittings or equipment on a flange plate each, and between the two flanges, plus flange pads, bolts are fastened together to complete the connection. Some pipe fittings and equipment already have their own flanges, which are also flange connections. Flange connection is an important connection method for pipeline construction. The flange connection is easy to use and can withstand large pressures. In industrial pipes, in the home, the pipe diameter is small, and it is low pressure, and the flange connection is not visible. If you are in a boiler room or production site, there are flanged pipes and equipment everywhere. [1]

According to the connection method, the types of flange connections can be divided into: plate flat welding flange, flat welding flange with neck, butt welding flange with neck, socket welding flange, threaded flange, flange cover, loose sleeve flange with neck butt welding ring, loose flange of flat welding ring, ring groove surface flange and flange cover, large diameter flat flange, large diameter high neck flange, figure-eight blind plate, butt welding ring loose flange, etc

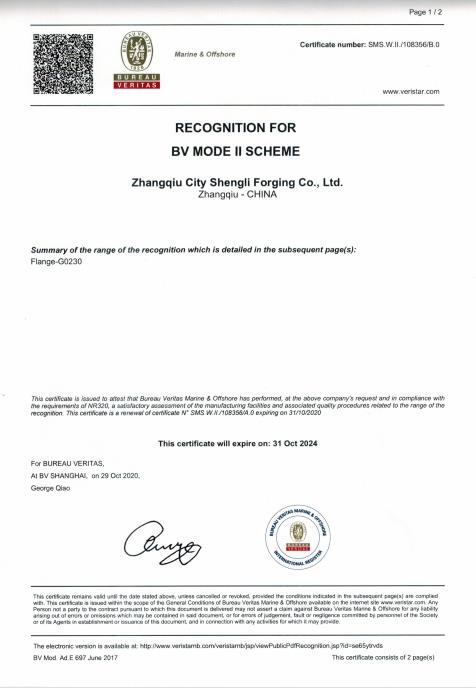

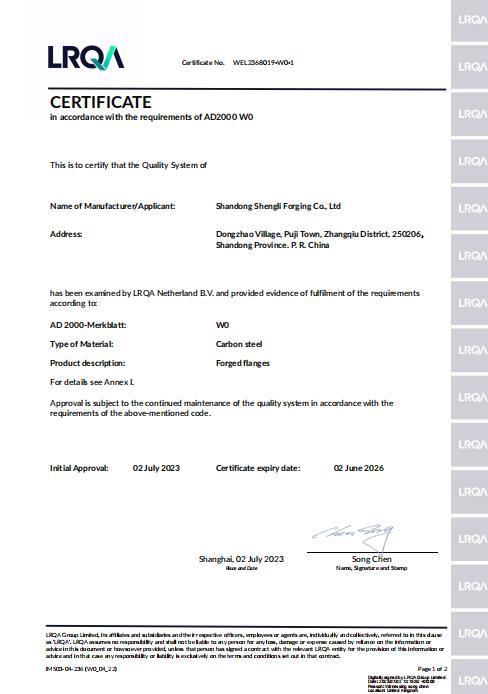

Shandong Shengli Forging Co., Ltd. is positioned in Zhangqiu City, Shandong Province, which is beautiful and affluent and has the reputation of "the vicinity of foundation of blacksmiths in China". It is positioned in Jinan City in the West and Qingdao port in the East. The organisation has nearly 5 years of specialist manufacturing history, rich ride and complete technical data. It has a set of awesome forging, machining, assembly, inspection and packaging manufacturing lines, The product first-rate completely conforms to the national and international standards.