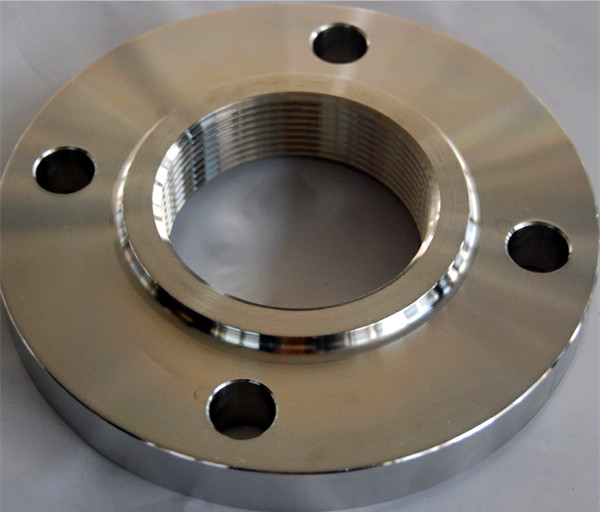

Threaded Flange DIN

A threaded flange refers to a type of flange that is connected to a pipeline using threads. When designing, it can be treated as a loose flange. The advantage is that welding is not required, and the additional torque generated by flange deformation on the cylinder or pipeline is very small. The disadvantage is that the flange thickness is large and the cost is high. Suitable for connecting high-pressure pipelines.

Threaded flange refers to a kind of flange that uses a thread to connect with a pipe. When designing, it can be treated according to the loose flange. The advantage is that no welding is required, and the additional torque generated on the cylinder or pipe when the flange is deformed is very small. The disadvantage is that the flange thickness is large and the cost is higher. Suitable for connection of high-pressure pipes.

Threaded flange is a non-welded flange that processes the inner hole of the flange into a pipe thread and connects with the threaded pipe. Compared with flat welding flanges or butt welding flanges, threaded flanges have the characteristics of convenient installation and maintenance, and can be used on pipelines that are not allowed to be welded on some sites. The alloy steel flange has sufficient strength, but it is not easy to weld, or the welding performance is not good, you can also choose the threaded flange. However, under the condition that the temperature of the pipeline changes sharply or the temperature is higher than 260 ° C and lower than -45 ° C, it is recommended not to use the threaded flange to avoid leakage.

Characteristics of carbon steel flanges: 1. corrosion resistance

2. right finish

3. handy safety

4. easy to weld

5. Durable and long lasting

1. Standard: | DIN2573 DIN2576 DIN2543 DIN2544 DIN2545 DIN2527 DIN2631 DIN2632 DIN2633 DIN2634 DIN2635 | |

2. Type: | SLIP-ON BLIND WEIDING NECK | |

3. Pressure Class: | 6BAR 10BAR 16BAR 25BAR 40BAR | |

4. Dimension: | DN10-DN1000 | |

5. Surface Treament: | Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc. | |

6. Raw Material: | RST 37.2; P245GH ; S235JR | |

7. Packing: | Wooden Case, Pallet. | |

8. Payment: | L/C, T/T | |

9. Delivery time: | 30 ~60 days after confirm the order | |

1. Standard: | DIN2573 DIN2576 DIN2543 DIN2544 DIN2545 DIN2527 DIN2631 DIN2632 DIN2633 DIN2634 DIN2635 | |

2. Type: | SLIP-ON BLIND WEIDING NECK | |

3. Pressure Class: | 6BAR 10BAR 16BAR 25BAR 40BAR | |

4. Dimension: | DN10-DN1000 | |

5. Surface Treament: | Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc. | |

6. Raw Material: | RST 37.2; P245GH ; S235JR | |

7. Packing: | Wooden Case, Pallet. | |

8. Payment: | L/C, T/T | |

9. Delivery time: | 30 ~60 days after confirm the order | |