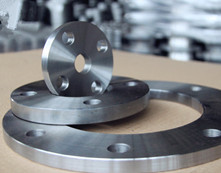

PN6 TYPE 01 Plate Flange

En 1092-1 type01 plate flanges can be forged, warmth treated, or hardened to reap higher strength.

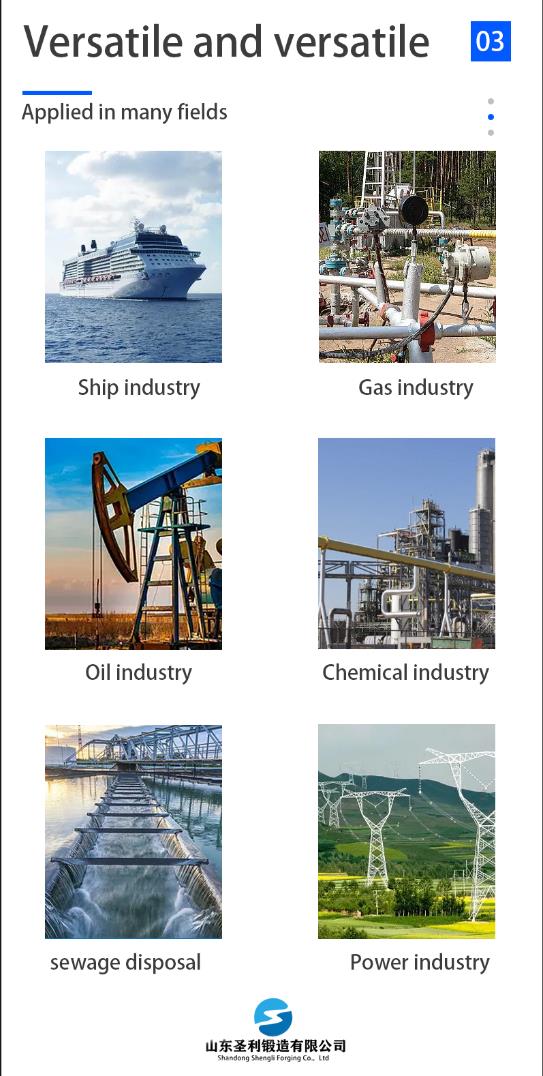

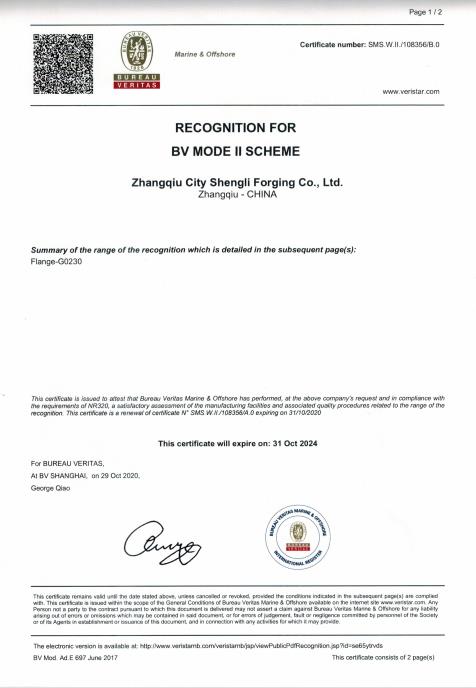

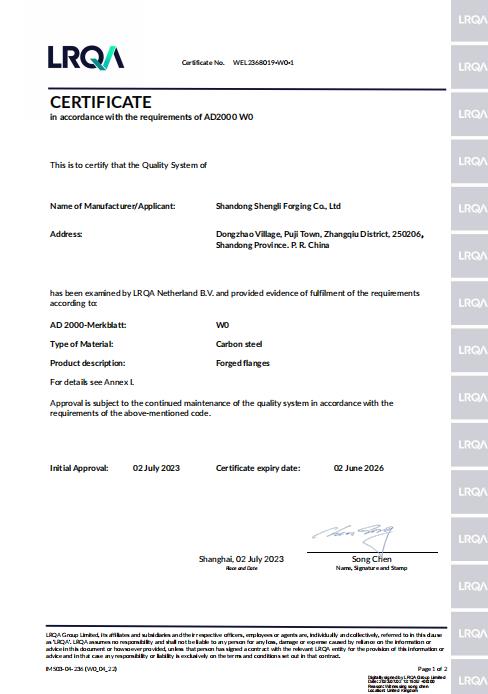

Shandong Shengli Forging Co., Ltd. specializes in producing various types of flanges, gear rings, and forgings. We welcome customers to visit and inspect

1. According to the chemical industry (HG) industry standard: integral flange (IF), threaded flange (Th), plate flat welding flange (PL), neck butt welding flange (WN), neck flat welding flange (SO), socket welding flange (SW), butt welding ring loose flange (PJ/SE), flat welding ring loose flange (PJ/RJ), lining flange cover (BL (S)), flange cover (BL) [2].

2. According to the petrochemical (SH) industry standard: thread flange (PT), butt welding flange (WN), flat welding flange (SO), socket welding flange (SW), loose flange (LJ), flange cover (no table note).

3. According to the mechanical (JB) industry standard: integral flange, butt welding flange, plate flat welding flange, butt welding ring loose flange, flat welding ring loose flange, flange ring loose flange, flange cover.

4. According to the national (GB) standard: integral flange, threaded flange, butt welding flange, flat welding flange with neck, socket welding flange with neck, butt welding ring with neck loose flange, plate flat welding flange, butt welding ring plate loose flange, flat welding ring plate loose flange, flange ring loose flange, flange cover.

Required equipment

One set of manual electric welding equipment, one handle angle grinder, one electric air hammer, and one flat ruler.

Pre-weld preparation

1. Check and debug the equipment to ensure the normal operation of the equipment; 2. Prepare φ4.0J402 welding rod, it is best to dry it at 300°C-350°C for one hour.

Welding process

1. Assemble the cone body and the large flange together according to the requirements of the drawing, and then divide the large flange into 8 equal parts on average.

2. Welding due to thicker flanges and larger grooves, segmented symmetrical and multi-layer welding is adopted.

Weld quality

The weld strength is required to be at least the strength of the base metal. The surface of the weld is smooth and smooth, and there are no defects such as burn-through, porosity, welding leakage, slag inclusion, undercut, and not welded. The residual height is less than 2mm.

Notes

1. When priming, J506 welding rod must be used for manual overlay welding, and small current welding is adopted. Welding in strict accordance with the welding process.

2. After each position of welding, use a horizontal ruler to check the deformation of the flange plane.

3. Hammer the weld with an air hammer while welding to achieve the effect of stress relief.

1. Standard: | EN1092-1 | |

2. Type: | Type 01 ;Type 05; | |

3. Pressure Class: | PN6;PN10; PN16; PN25; PN40 | |

4. Dimension: | DN10-DN2000 | |

5. Surface Treament: | Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc. | |

6. Raw Material: | RST 37.2; P245GH ; S235JR | |

7. Packing: | Wooden Case, Pallet. | |

8. Payment: | L/C, T/T | |

9. Delivery time: | 30 ~60 days after confirm the order | |

1. Standard: | EN1092-1 | |

2. Type: | Type 01 ;Type 05; | |

3. Pressure Class: | PN6;PN10; PN16; PN25; PN40 | |

4. Dimension: | DN10-DN2000 | |

5. Surface Treament: | Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc. | |

6. Raw Material: | RST 37.2; P245GH ; S235JR | |

7. Packing: | Wooden Case, Pallet. | |

8. Payment: | L/C, T/T | |

9. Delivery time: | 30 ~60 days after confirm the order | |