JIS 5K Sopff Flange

Flat Flange Strength Manufacturer Aesthetic appearance Support processing and customization

Product material: carbon steel

Connection mode: welding

Product characteristics: low steel value, strong elasticity

Our company can produce various specifications of stainless steel, alloy steel, carbon steel flange series products according to standards; The products have undergone strict quality inspection, constantly improving in size and quality, and are widely sold at home and abroad, obtaining consistent praise from customers at home and abroad.

As an iron plate welding flange, many clients have questions about whether or not the great of the iron plate welding flange is higher than that of the solid welding flange. In fact, the excellent of the iron plate welding flange and the excellent of the solid welding flange are the same, however the place can the iron plate welding flange no longer be guaranteed, that is, the cloth of the iron plate welding flange is the most unguaranteed, due to the fact in the universal process, the density of the iron plate welding flange is no problem, however in the procedure of production, the clean of the iron plate welding flange is hardly ever tested, so after the production, the cloth of the iron plate welding flange that has no longer been examined can't be guaranteed.

Required equipment

One set of guide electric powered welding equipment, one take care of attitude grinder, one electric powered air hammer, and one flat ruler.

Pre-weld preparation

1. Check and debug the tools to make sure the everyday operation of the equipment; two Prepare φ4.0J402 welding rod, it is first-rate to dry it at 300°C-350°C for one hour.

Welding process

1. Assemble the cone physique and the giant flange collectively in accordance to the necessities of the drawing, and then divide the massive flange into eight equal components on average.

2. Welding due to thicker flanges and large grooves, segmented symmetrical and multi-layer welding is adopted.

Weld quality

The weld energy is required to be at least the electricity of the base metal. The floor of the weld is clean and smooth, and there are no defects such as burn-through, porosity, welding leakage, slag inclusion, undercut, and no longer welded. The residual peak is less than 2mm.

Notes

1. When priming, J506 welding rod should be used for guide overlay welding, and small cutting-edge welding is adopted. Welding in strict accordance with the welding process.

2. After every function of welding, use a horizontal ruler to test the deformation of the flange plane.

3. Hammer the weld with an air hammer whilst welding to attain the impact of stress relief.

Characteristics of carbon metal flanges:

1. No worry of corrosion

2. Good smoothness

3. Convenient maintenance

4. Easy to weld

5. Durable and long lasting

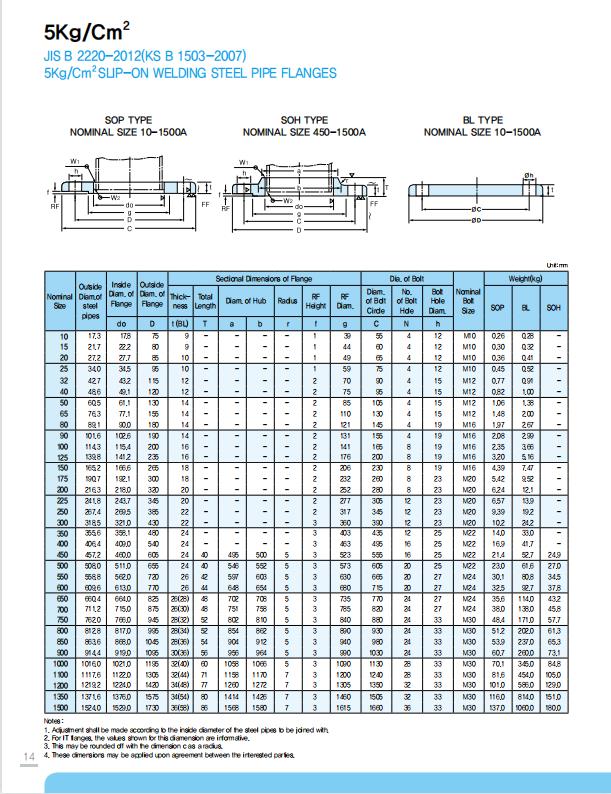

1. Standard: | JIS B2220 | |

2. Type: | SOP; SOH | |

3. Pressure Class: | 5k;10k;16k;30K:40K | |

4. Dimension: | 10A-1200A | |

5. Surface Treament: | Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc. | |

6. Raw Material: | SS400 | |

7. Packing: | Wooden Case, Pallet. | |

8. Payment: | L/C, T/T | |

9. Delivery time: | 30 ~60 days after confirm the order | |

NO | MATERIAL | ITEM | SIZE | 数量(EA) | 单重(kg) | 总重(kg) | |

Q’TY | WEIGHT | TOTAL WEIGHT | |||||

303-4 | 1 | SS400 | 5K SOPFF | 80A | 1800 | 1.99 | 3582.00 |

2 | SS400 | 10K SOPFF | 20A | 3000 | 0.73 | 2190.00 | |

3 | SS400 | 10K SOPFF | 40A | 1400 | 1.56 | 2184.00 | |

4 | SS400 | 10K SOPFF | 125A | 500 | 4.77 | 2385.00 | |

5 | SS400 | 10K SOPFF | 150A | 1000 | 6.34 | 6340.00 | |

6 | SF440A | 16K SOHFF | 25A | 1000 | 1.16 | 1160.00 | |

7 | SF440A | 16K SOHFF | 40A | 1000 | 1.64 | 1640.00 | |

8 | SF440A | 16K SOHFF | 125A | 300 | 7.00 | 2100.00 | |

305-1 | 9 | SS400 | 5K SOPFF | 125A | 750 | 3.23 | 2422.50 |

305-4 | 10 | SS400 | 10K SOPFF | 65A | 1500 | 2.60 | 3900.00 |

306-1 | 11 | SS400 | 5K SOPFF | 150A | 1600 | 4.41 | 7056.00 |

12 | SS400 | 5K SOPFF | 250A | 800 | 9.45 | 7560.00 | |

LC | |||||||

14650 | 42519.50 | ||||||