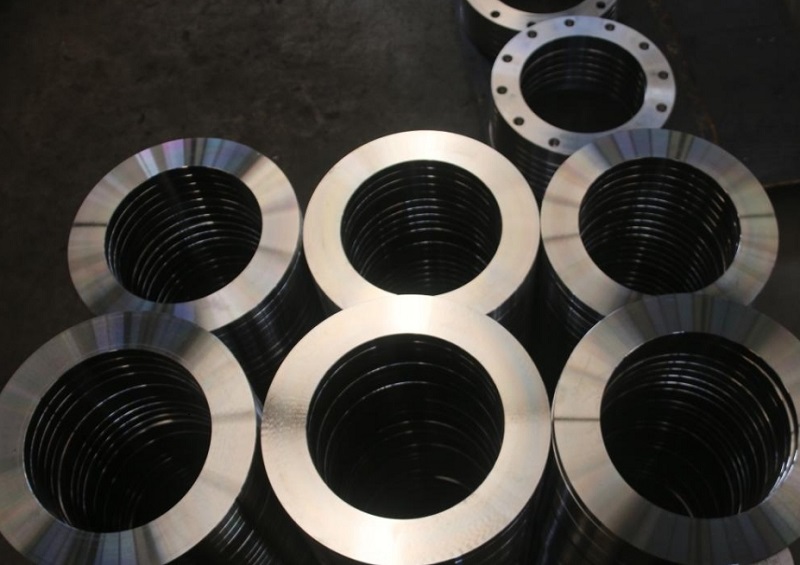

5K 200A SOP

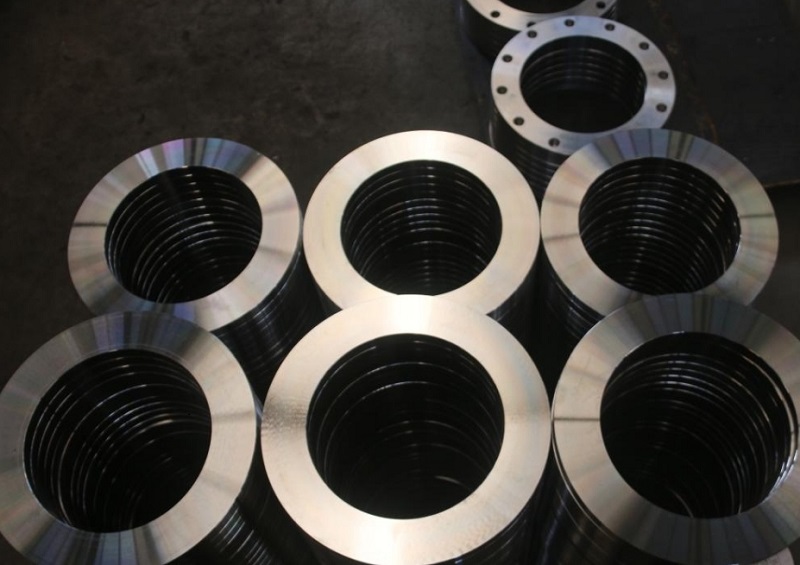

Product material: carbon steel

Product specifications: customizable according to customer requirements

Compressive strength: strong

Connection form: welding

Product characteristics: low stiffness value, good elasticity

Flat welded flanges are appropriate for pipeline structures with pretty low strain degrees and minimal stress fluctuations, vibrations, and vibrations. The gain of flat welding flanges is that they are less complicated to align all through welding and assembly, and their rate is incredibly cheap, making them broadly used.

Flat welded flange

Flat welding flanges consist of flat welding flanges and flat welding flanges with necks.

Flat welded flange (PL)

Flat welded flanges are appropriate for metal pipe connections with nominal stress now not exceeding 2.5MPa. The sealing floor of the flat welding flange can be made into three types: easy type, concave-convex kind and tongue and groove type. Smooth flat welded flanges are the most broadly used. It is ordinarily used when the medium prerequisites are incredibly moderate, such as low-pressure non-purified compressed air and low-pressure circulating water.

Flat welded flange with neck (SO)

The neck top of the flat welded flange with neck is low, and the stiffness and bearing potential of the flange are improved. Compared with butt welding flange, the welding workload is large, the electrode consumption is high, and it can't face up to excessive temperature and excessive stress and repeated bending and temperature fluctuations, however the on-site set up is greater convenient, and the procedure of welding seam kneading can be omitted, which is greater popular.

(5) Butt welding with neck (WN)

Butt welding flange: Neck flange welding is regularly referred to as a "high hub" flange. Its cause is to switch strain to the pipe, thereby decreasing excessive stress concentrations in the flange. Neck flange welding is quality designed to supply flanges for butt welding these due to their inherent structural value. However, the rate is especially high, due to the fact the manufacturing system of the product is complicated.

Threaded (threaded) flange: This threaded flange is related through a wire buckle. However, the middle of the product has a thread dimension corresponding to the tube. Its essential benefit is that it can be assembled besides welding.

In addition, there are sliding flanges and lap flanges.

1. Standard: | ||

2. Type: | SOP SOH | |

3. Pressure Class: | 5K 10K 16K 20K 30K 40K | |

4. Dimension: | 10A-1200A | |

5. Surface Treament: | Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc. | |

6. Raw Material: | SS400/SF440A | |

7. Packing: | Wooden Case, Pallet. | |

8. Payment: | L/C, T/T | |

9. Delivery time: | 30 ~60 days after confirm the order | |

1. Standard: | JIS B2220 | |

2. Type: | SOP SOH | |

3. Pressure Class: | 5K 10K 16K 20K 30K 40K | |

4. Dimension: | 10A-1200A | |

5. Surface Treament: | Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc. | |

6. Raw Material: | SS400/SF440A | |

7. Packing: | Wooden Case, Pallet. | |

8. Payment: | L/C, T/T | |

9. Delivery time: | 30 ~60 days after confirm the order | |