5Kg 350A Sop

The benefits of flat welded flanges are as follows:

1. Flat welded flanges are less difficult to align at some point of welding and assembly, making set up easy and convenient;

2. Widely used, it can be utilized in a range of industries such as metallurgy, machinery, chemical engineering, petroleum, computer tools, water conservancy, construction, engineering, shipbuilding, environmental protection, coal, agricultural machinery, food, boilers, stress vessels, etc;

3. Beautiful appearance, flat and easy floor of flat welded flanges, in the main used for connecting carbon metal pipes;

4. Easy to disassemble and investigate pipeline conditions;

5. Connecting pipelines and flat welding flanges can additionally preserve pipeline sealing performance.

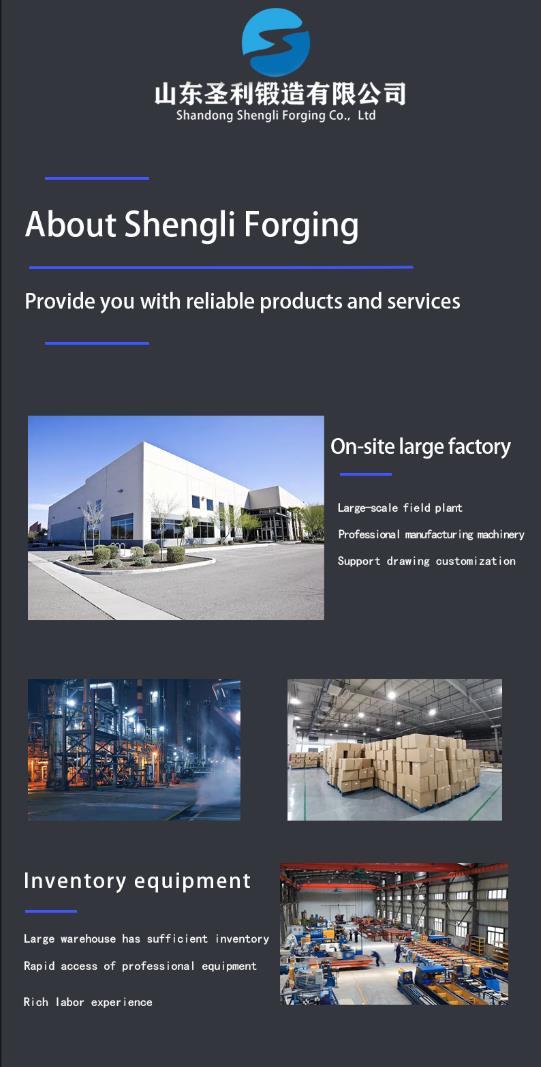

Shandong Shengli Forging Co.ltd. was once headquartered in 2008, now there are eighty workers, worldwide income personnel 5 , pleasant inspection personnel 6. Monthly output can attain 600 tons. Production, packaging, laboratory trying out gear available. We specialize in producing carbon metal flanges.

The application fields of ring forgings are:

Diesel engine ring forging: a kind of diesel engine forging, diesel engine diesel engine diesel engine is a kind of power machinery, it is commonly used as an engine. Taking large diesel engines as an example, the forgings used include cylinder heads, main journals, crankshaft end flange output end shafts, connecting rods, piston rods, piston heads, crosshead pin shafts, crankshaft transmission gears, ring gears, intermediate gears and oil dyeing pump bodies.

Marine ring forgings: Marine forgings are divided into three categories, main engine forgings, shaft forgings and rudder forgings. Main engine forgings are the same as diesel engine forgings. Shafting forgings include thrust shaft, intermediate shaft, stern shaft, etc. Rudder forgings include rudder rods, rudder posts, rudder pins, etc.

Ordnance ring forgings: Forgings occupy an extremely important position in the weapons industry. In terms of weight, 60% of the tanks are forgings. Barrels, muzzle brakes and tails in artillery, rifled barrels and three-sided bayonets in infantry weapons, rocket and submarine deep-water launchers and mounts, stainless steel valve bodies for high-pressure coolers for nuclear submarines, shells, gun shells, etc., are all forged products. In addition to steel forgings, weapons are also made from other materials.

Petrochemical ring forgings: Forgings have a wide range of applications in petrochemical equipment. Such as the manhole and flange of the spherical storage tank, the various tube sheets required for the heat exchanger, the forging cylinder (pressure vessel) of the butt welded flange catalytic cracking reactor, the cylinder section used in the hydrogenation reactor, and the top cover, bottom cover, head, etc. required by fertilizer equipment are forgings.

Mining ring forgings: According to the weight of the equipment, the proportion of forgings in mining equipment is 12-24%. Mining equipment includes: mining equipment, hoist equipment, crushing equipment, grinding equipment, washing equipment, sintering equipment.

Nuclear power ring forgings: Nuclear power is divided into two categories: pressurized water reactor and boiling water reactor. The main large forgings of nuclear power plants can be divided into two categories: pressure shells and reactor internal components. The pressure shell contains: cylinder flange, nozzle section, nozzle, upper cylinder, lower cylinder, cylinder transition section, bolt, etc. The internal components of the pile work under severe conditions such as high temperature, high pressure, strong neutron irradiation, boric acid water corrosion, erosion and hydraulic vibration, so 18-8 austenitic stainless steel should be selected.

Thermal power ring forgings: There are four key forgings in thermal power generation equipment, namely the rotor and guard ring of the turbine generator, and the impeller and steam turbine rotor in the steam turbine.

Hydropower ring forgings: Important forgings in hydroelectric power station equipment include large shafts of hydroelectric turbines, large shafts of hydroelectric generators, mirror plates, thrust heads, etc.

1. Standard: | JIS B2220 | |

2. Type: | SOP SOH | |

3. Pressure Class: | 5K 10K 16K 20K 30K 40K | |

4. Dimension: | 10A-1200A | |

5. Surface Treament: | Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc. | |

6. Raw Material: | SS400/SF440A | |

7. Packing: | Wooden Case, Pallet. | |

8. Payment: | L/C, T/T | |

9. Delivery time: | 30 ~60 days after confirm the order | |

1. Standard: | ||

2. Type: | SOP SOH | |

3. Pressure Class: | 5K 10K 16K 20K 30K 40K | |

4. Dimension: | 10A-1200A | |

5. Surface Treament: | Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc. | |

6. Raw Material: | SS400/SF440A | |

7. Packing: | Wooden Case, Pallet. | |

8. Payment: | L/C, T/T | |

9. Delivery time: | 30 ~60 days after confirm the order | |