JIS 30K S/40 Flange

Product material: carbon steel

Product specifications: customizable according to customer requirements

Compressive strength: strong

Connection form: welding

Product characteristics: low stiffness value, good elasticity

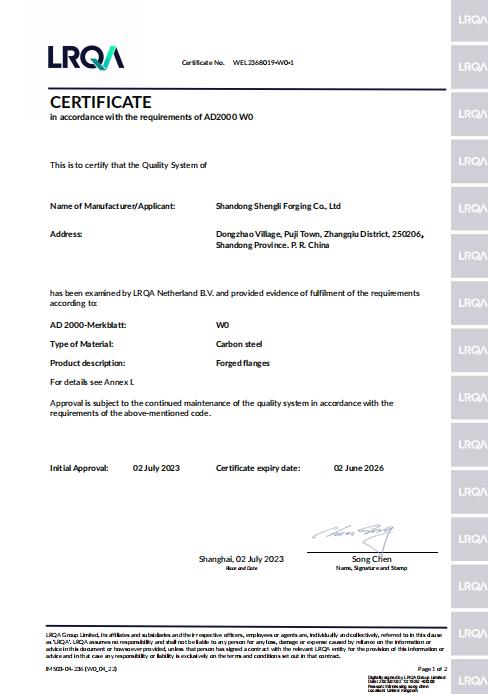

Our company currently mainly exports to countries and regions such as South Korea, Japan, Europe and America. Our company has various qualifications and certifications, and is a modern chemical factory that integrates research and development, innovation, production and processing.

Forged flange connection is to put two pipes, pipe fittings or equipment, and forged flange connection is an important connection method for pipeline construction. Forged flange connections are easy to use and can withstand large pressures. In industrial pipelines, forged flange connections are widely used. In the home, the pipe diameter is small, and the low pressure is low, and the connection of the flange stamping elbow is not visible. If you are in a boiler room or production site, there are flanged pipes and equipment everywhere. Chromium content 0.1% ~ 0.5% (forged flange generally does not contain chromium), carbon content below 1.0% and forged flange by high temperature forging manufacturing, some forged flange surface hardness (HRC) although can reach ≥ 56 or more (quenching layer only about 15mm), because the forging flange material hardenability is poor, its core hardness is generally only more than 30 degrees, under normal circumstances, forged flange often uses water quenching treatment.

Flange protection cover (flange protection joint)

Flange protective covers are mainly used for flange connection corrosion protection in all industries. The flange protection head of this product is used to protect the flange face (convex or annular joint). Double studs and gaskets are protected from corrosion. The product is suitable for 316 ss stainless steel as well as non-metallic (plastic) and is available in sizes from 1/2" to 144" ANSI, API and AWWA flange connection diameters. The flange head system combined with the flange packing protects in harsh application environments.

1. Standard: | JIS B2220 | |

2. Type: | SOP SOH | |

3. Pressure Class: | 5K 10K 16K 20K 30K 40K | |

4. Dimension: | 10A-1200A | |

5. Surface Treament: | Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc. | |

6. Raw Material: | SS400/SF440A | |

7. Packing: | Wooden Case, Pallet. | |

8. Payment: | L/C, T/T | |

9. Delivery time: | 30 ~60 days after confirm the order | |

1. Standard: | ||

2. Type: | SOP SOH | |

3. Pressure Class: | 5K 10K 16K 20K 30K 40K | |

4. Dimension: | 10A-1200A | |

5. Surface Treament: | Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc. | |

6. Raw Material: | SS400/SF440A | |

7. Packing: | Wooden Case, Pallet. | |

8. Payment: | L/C, T/T | |

9. Delivery time: | 30 ~60 days after confirm the order | |