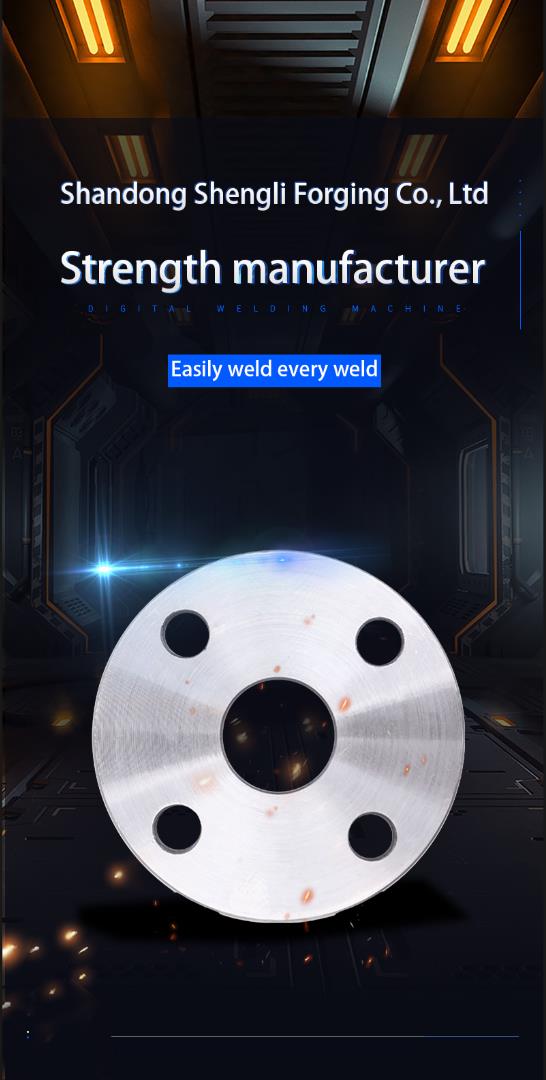

JIS 5K SET ON Flange

Product material: carbon steel

Product specifications: customizable according to customer requirements

Compressive strength: strong

Connection form: welding

Product characteristics: low stiffness value, good elasticity

Our company has various types of forging equipment such as presses and air hammers, which can produce various types of flanges and forgings. We also have various CNC processing equipment and a complete inspection system. We welcome customers to purchase.

(1) Casting flange and forged flange

The cast flange, blank shape and size is accurate, the processing volume is small, the cost is low, but there are casting defects (pores. Crack. inclusions); The internal structure of the casting is poorly streamlined (if it is a cutting part, the streamlined type is worse);

Forged flanges generally have lower carbon content than casting flanges and are not easy to rust, forgings have good streamlining, relatively dense structure, and mechanical properties are better than casting flanges;

Improper forging process will also cause large or uneven grains, hardening cracks, and forging costs are higher than casting flanges.

Forgings can withstand higher shear and tensile forces than castings.

The advantage of castings is that they can manufacture more complex shapes and low costs;

The advantage of forgings is that the internal structure is uniform, and there are no harmful defects such as pores and inclusions in the castings;

From the production process, the difference between casting flange and forging flange, such as centrifugal flange, belongs to a kind of casting flange.

Centrifugal flange belongs to the precision casting method production flange, this kind of casting than ordinary sand casting structure is much finer, the quality is improved a lot, not easy to appear tissue looseness, porosity, trachoma and other problems.

First of all, we need to understand how centrifugal flanges are produced, centrifugal casting to make flat welding flange process methods and products, which are characterized by the following process steps processing:

(1) Put the selected raw material steel into the medium frequency electric furnace for melting, so that the temperature of molten steel reaches 1600-1700 °C;

(2) Preheat the metal mold to 800-900°C to maintain a constant temperature;

(3) Start the centrifuge and inject the molten steel in step (1) into the preheated metal mold in step (2);

(4) The casting is naturally cooled to 800-900 °C for 1-10 minutes;

(5) Cool with water to close to normal temperature, and remove the casting from the mold.

1. Standard: | JIS B2220 | |

2. Type: | SOP SOH | |

3. Pressure Class: | 5K 10K 16K 20K 30K 40K | |

4. Dimension: | 10A-1200A | |

5. Surface Treament: | Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc. | |

6. Raw Material: | SS400/SF440A | |

7. Packing: | Wooden Case, Pallet. | |

8. Payment: | L/C, T/T | |

9. Delivery time: | 30 ~60 days after confirm the order | |

1. Standard: | ||

2. Type: | SOP SOH | |

3. Pressure Class: | 5K 10K 16K 20K 30K 40K | |

4. Dimension: | 10A-1200A | |

5. Surface Treament: | Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc. | |

6. Raw Material: | SS400/SF440A | |

7. Packing: | Wooden Case, Pallet. | |

8. Payment: | L/C, T/T | |

9. Delivery time: | 30 ~60 days after confirm the order | |