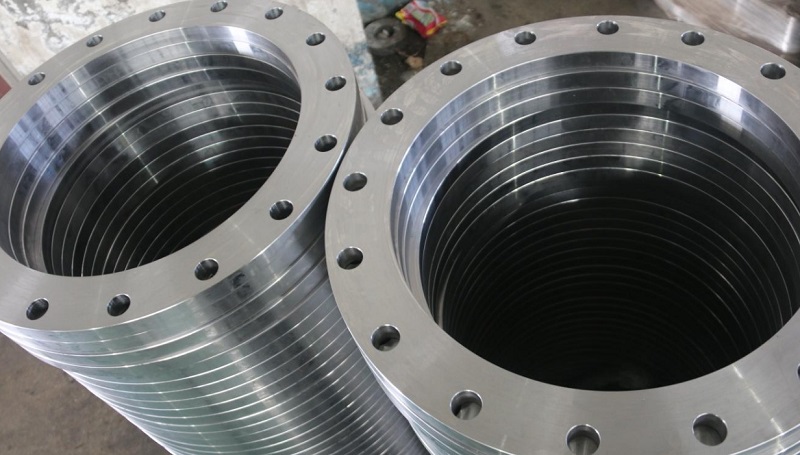

JIS 5K 250A SOP

Our company can produce various specifications of stainless steel, alloy steel, and carbon steel flange products according to standards; The product has undergone strict quality inspection, constantly striving for excellence in size and quality, and is widely sold both domestically and internationally, receiving unanimous praise from customers both domestically and internationally.

Flange connection is a removable joint that first fixes two pipes, fittings, or tools to a flange, then provides a flange gasket between the two flanges, and sooner or later makes use of bolts to tighten the two flanges to tightly join them. The connection between stationary pipelines and rotating or reciprocating gear can be achieved.

1. Sliding line blanking:

Cut the ingots to a reasonable size and weight according to product requirements;

2. Heating (including tempering):

Heating equipment main single chamber furnace, pusher furnace and desktop annealing furnace, all heating furnaces are made of natural gas as fuel, the heating temperature of steel ingots is generally 1150 °C ~ 1240 °C, the heating time of cold ingots is about 1 ~ 5 hours, the heating time of hot ingots is half of the heating time of cold ingots, and the heated ingots enter the forging process.

3. Forging:

The steel ingot is heated to about 1150~1240 °C and taken out of the heating furnace, and then put into the air hammer or electro-hydraulic hammer by the manipulator, according to the size of the ingot and the forging ratio requirements to carry out the corresponding pier thickness, drawing and other processes, real-time monitoring of the size of the forging, and control the forging temperature through the infrared thermometer.

4. Inspection:

Preliminary inspection of forging blanks, mainly inspection of appearance and size. In terms of appearance, it is mainly inspected for defects such as cracks, and the size must ensure that the blank balance is within the scope required by the drawings and recorded.

5. Heat treatment:

A comprehensive process in which forgings are heated to a predetermined temperature, kept warm for a certain period of time, and then cooled at a predetermined speed to improve the internal structure and properties of forgings. Its purpose is to eliminate internal stress, prevent deformation during machining, and adjust the hardness to make forgings conducive to machining. After heat treatment, the ingot is air-cooled or water-cooled and quenched according to the requirements of the material.

1. Standard: | ||

2. Type: | SOP SOH | |

3. Pressure Class: | 5K 10K 16K 20K 30K 40K | |

4. Dimension: | 10A-1200A | |

5. Surface Treament: | Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc. | |

6. Raw Material: | SS400/SF440A | |

7. Packing: | Wooden Case, Pallet. | |

8. Payment: | L/C, T/T | |

9. Delivery time: | 30 ~60 days after confirm the order | |

1. Standard: | JIS B2220 | |

2. Type: | SOP SOH | |

3. Pressure Class: | 5K 10K 16K 20K 30K 40K | |

4. Dimension: | 10A-1200A | |

5. Surface Treament: | Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc. | |

6. Raw Material: | SS400/SF440A | |

7. Packing: | Wooden Case, Pallet. | |

8. Payment: | L/C, T/T | |

9. Delivery time: | 30 ~60 days after confirm the order | |

1. Standard: | JIS B2220 | |

2. Type: | SOP SOH | |

3. Pressure Class: | 5K 10K 16K 20K 30K 40K | |

4. Dimension: | 10A-1200A | |

5. Surface Treament: | Anti-rust oil; Yellow paint; Black paint;Hot dip Galavnised; Zinc. | |

6. Raw Material: | SS400/SF440A | |

7. Packing: | Wooden Case, Pallet. | |

8. Payment: | L/C, T/T | |

9. Delivery time: | 30 ~60 days after confirm the order | |